+86 25 52164810 sales@suntech-metal.com

Views: 0 Author: Site Editor Publish Time: 2022-01-05 Origin: Site

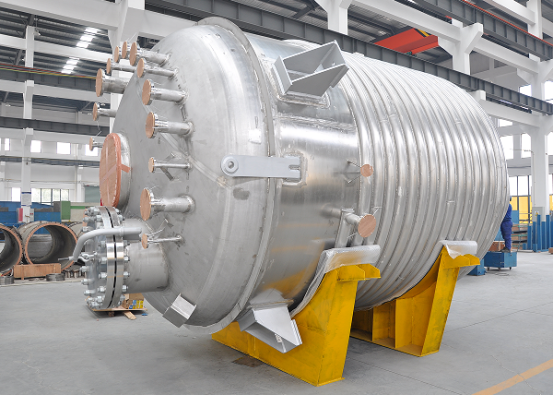

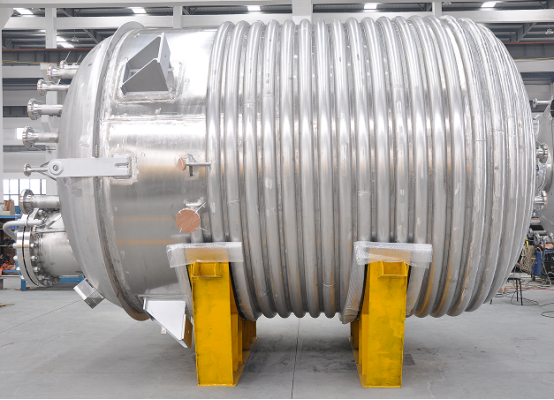

We have the honor to participate in the bactericide expansion project of a British company, designing and manufacturing 6 sets of half pipe reactors made of super duplex steel 2507. Because the equipment has half pipe, the customer has the following extremely high requirements for half pipe welding:

1、Outer bevel for half pipe;

2、Half pipe mock-up test & welder qualification;

3、Half pipe butt weld 100% PT+ 100% RT;

4、Half pipe fillet weld 100% PT;

5、Half pipe welds need full penetration;

6、Half pipe fillet welds 100% endoscopy inspection.

7、Argon protection is required for the whole process of half pipe welding. Oxygen meter is required to ensure that oxygen content shall not exceed 0.5% before welding;

8、All half pipe welds shall be welded twice by argon arc welding;

9、After half pipe welding is completed, conducting hydrostatic test and maintain the pressure for 60 minutes;

10、Half pipe welding needs 0.1mm aluminum foil paper or thermal tape protection;

In the course of 3 months' design, manufacture and inspection, we overcome many difficulties, including COVID-19, power limitation and so on. We withstood the customer's layers of inspection and finally successfully realized the delivery.

This project tested the team's ability and execution, and laid a solid foundation for the company's in-depth cooperation with the customer in future projects.